NEW TECHNOLOGIES

The Technical Staff at ![]() are currently developing a new range of revolutionary coatings that provide contractors and DIY users with spectacular durability and specialist finishes.

are currently developing a new range of revolutionary coatings that provide contractors and DIY users with spectacular durability and specialist finishes.

New Inventions and technologies under development are:-

THERMO STATIC – Heat Reflectant coatings

MARBLE GLAZE – A unique 2 coat system that creates an instant Marble Finish on most surfaces.

TILE GLAZE – A Revolutionary System that changes the appearance of Tiles into a New Glass Like Finish

3D CRYSTAL GLAZE – Paint coatings that form a 3D Effect in 2 Colour Tones.

LIQUID STONE – A new reactive paint that forms a Natural Stone Finish on most surfaces.

Steven Lamp

The distinctive design of the Steven lamp is sure to capture your attention, presenting itself as a superb choice for various settings. It presents a fantastic chance to introduce a hint of elegance to your workspace, dining area, or any room in need of a contemporary touch.

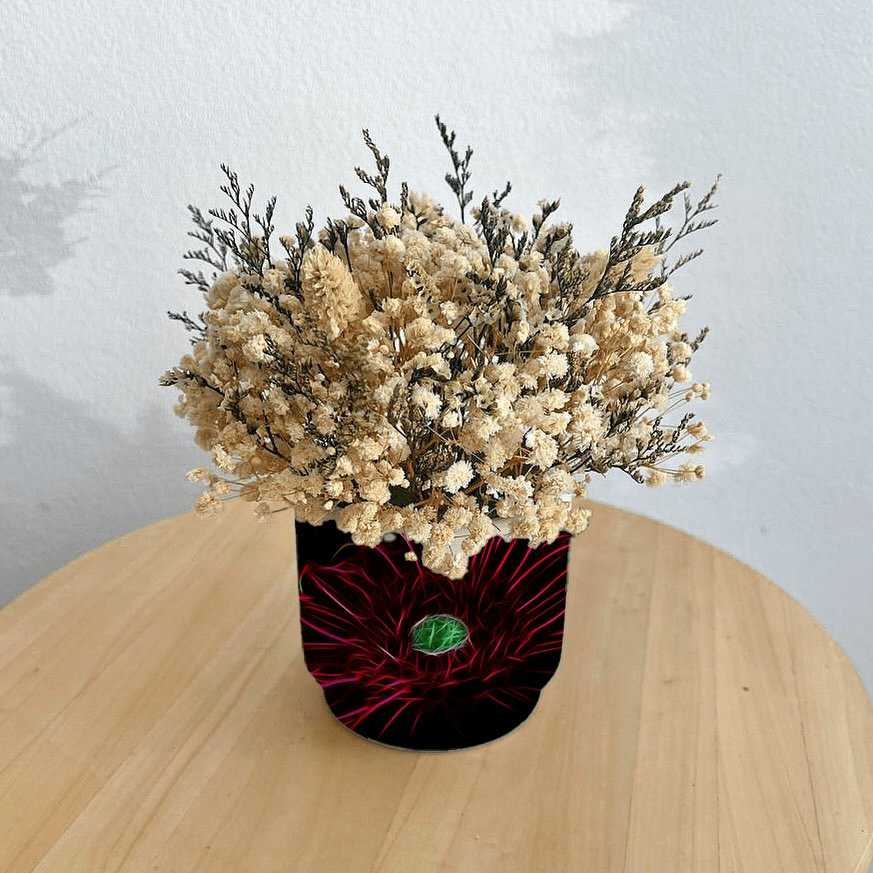

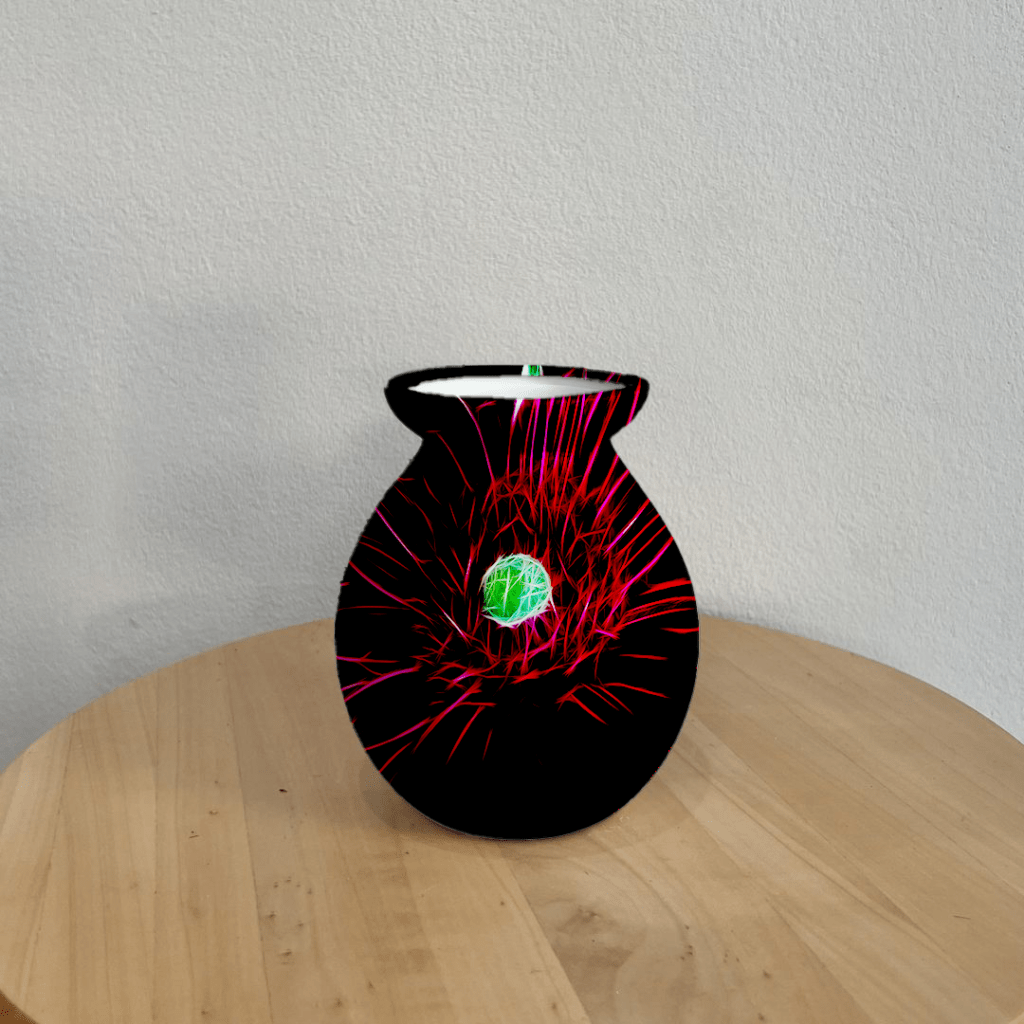

Steven Flower Vase

The distinctive design of the Steven Vase is sure to capture your attention, presenting itself as a superb choice for various settings. It presents a fantastic chance to introduce a hint of elegance to your workspace, dining area, or any room in need of a contemporary touch.

Steven Vase

The distinctive design of the Steven Vase is sure to capture your attention, presenting itself as a superb choice for various settings. It presents a fantastic chance to introduce a hint of elegance to your workspace, dining area, or any room in need of a contemporary touch.

Donald Lamp

The unique style of the Donald lamp is bound to catch your eye, making it an excellent option for a range of environments. It offers a wonderful opportunity to add a touch of sophistication to your office, dining room, or any space that could use a modern flair.

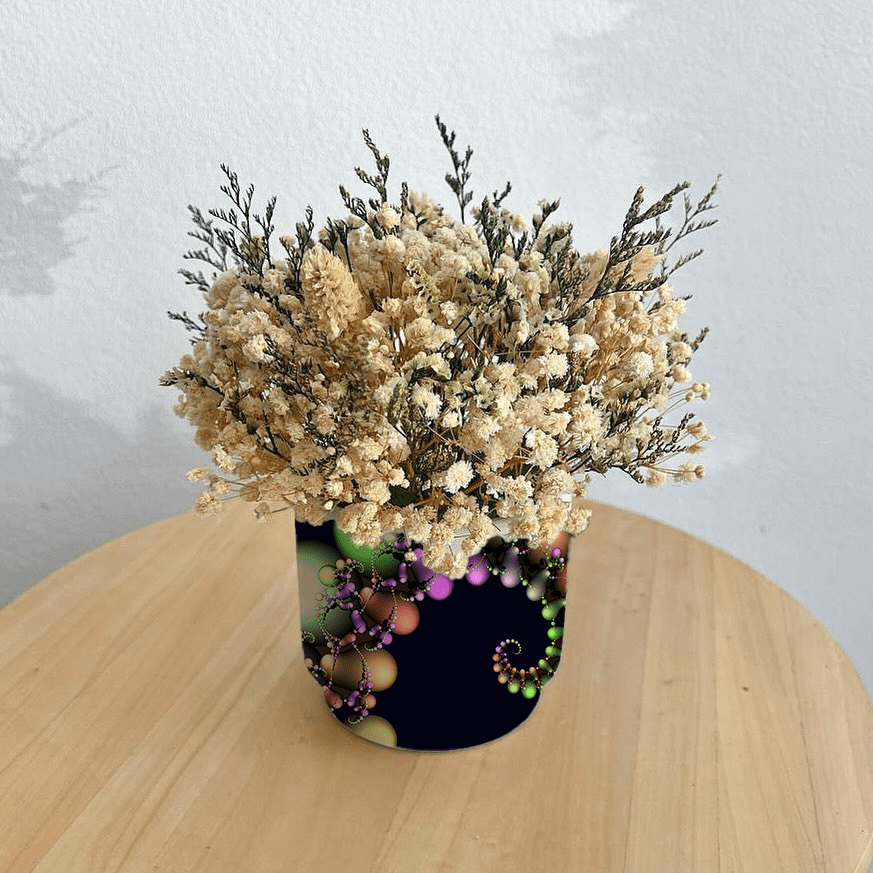

Donald Flower Vase

The unique style of the Donald Vase is bound to catch your eye, making it an excellent option for a range of environments. It offers a wonderful opportunity to add a touch of sophistication to your office, dining room, or any space that could use a modern flair.

Donald Vase

The unique style of the Donald Vase is bound to catch your eye, making it an excellent option for a range of environments. It offers a wonderful opportunity to add a touch of sophistication to your office, dining room, or any space that could use a modern flair.

Timothy Lamp

The distinctive design of the Timothy lamp is sure to capture your interest, providing a great choice for various settings. It presents a perfect chance to introduce a hint of elegance to your workspace, dining area, or any room in need of a trendy touch.

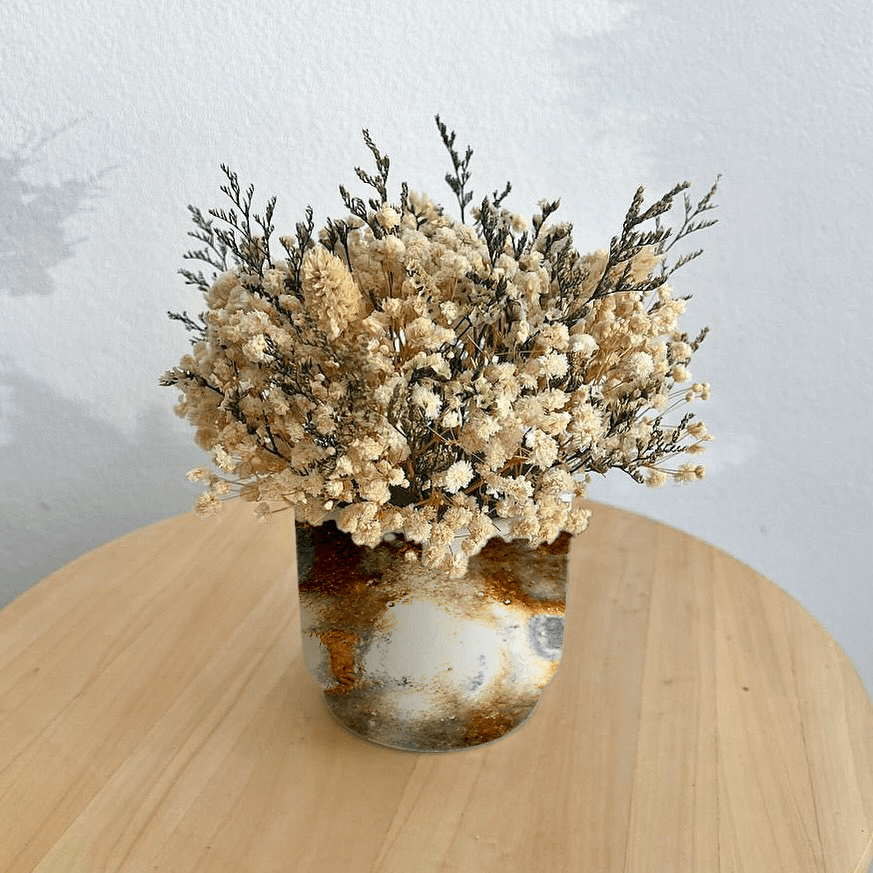

Timothy Flower Vase

The distinctive design of the Timothy Vase is sure to capture your interest, providing a great choice for various settings. It presents a perfect chance to introduce a hint of elegance to your workspace, dining area, or any room in need of a trendy touch.

Timothy Vase

The distinctive design of the Timothy Vase is sure to capture your interest, providing a great choice for various settings. It presents a perfect chance to introduce a hint of elegance to your workspace, dining area, or any room in need of a trendy touch.

Kevin Lamp

The unique design of the Kevin lamp is guaranteed to catch your attention, making it an excellent option for a range of environments. It offers an ideal opportunity to add a touch of style to your office, dining room, or any space that could benefit from a fashionable accent.

Kevin Flower Vase

The unique design of the Kevin Vase is guaranteed to catch your attention, making it an excellent option for a range of environments. It offers an ideal opportunity to add a touch of style to your office, dining room, or any space that could benefit from a fashionable accent.

Kevin Vase

The unique design of the Kevin Vase is guaranteed to catch your attention, making it an excellent option for a range of environments. It offers an ideal opportunity to add a touch of style to your office, dining room, or any space that could benefit from a fashionable accent.

Jason Lamp

The Jason lamp’s one-of-a-kind appearance is sure to grab your eye, making it a great choice for various settings. It provides the perfect chance to bring some flair to your workspace, dining space, or any area in need of a trendy accent.

Jason Flower Vase

The Jason vase’s one-of-a-kind appearance is sure to grab your eye, making it a great choice for various settings. It provides the perfect chance to bring some flair to your workspace, dining space, or any area in need of a trendy accent.

Jason Vase

The Jason vase’s one-of-a-kind appearance is sure to grab your eye, making it a great choice for various settings. It provides the perfect chance to bring some flair to your workspace, dining space, or any area in need of a trendy accent.

Edward Lamp

The unique look of the Edward lamp will definitely catch your attention, making it a wonderful option for different places. It gives you a perfect opportunity to add a bit of style to your office, dining area, or any room that could use a fashionable touch.

Edward Flower Vase

The unique look of the Edward Vase will definitely catch your attention, making it a wonderful option for different places. It gives you a perfect opportunity to add a bit of style to your office, dining area, or any room that could use a fashionable touch.

Edward Vase

The unique look of the Edward Vase will definitely catch your attention, making it a wonderful option for different places. It gives you a perfect opportunity to add a bit of style to your office, dining area, or any room that could use a fashionable touch.

Jeffrey Lamp

The distinctive design of the Jeffrey lamp is sure to grab your eye, offering a fantastic choice for various settings. It offers a great chance to bring a touch of elegance to your workspace, dining room, or any space in need of a chic accent.

Jeffrey Flower Vase

The distinctive design of the Jeffrey Vase is sure to grab your eye, offering a fantastic choice for various settings. It offers a great chance to bring a touch of elegance to your workspace, dining room, or any space in need of a chic accent.

Jeffrey Vase

The distinctive design of the Jeffrey Vase is sure to grab your eye, offering a fantastic choice for various settings. It offers a great chance to bring a touch of elegance to your workspace, dining room, or any space in need of a chic accent.

Ryan Lamp

The unique aesthetic of the Ryan lamp is bound to catch your attention, providing an excellent option for a range of environments. It presents a wonderful opportunity to add a hint of sophistication to your office, dining area, or any room requiring a stylish touch.

Ryan Flower Vase

The unique aesthetic of the Ryan vase is bound to catch your attention, providing an excellent option for a range of environments. It presents a wonderful opportunity to add a hint of sophistication to your office, dining area, or any room requiring a stylish touch.

Ryan Vase

The unique aesthetic of the Ryan vase is bound to catch your attention, providing an excellent option for a range of environments. It presents a wonderful opportunity to add a hint of sophistication to your office, dining area, or any room requiring a stylish touch.

Jacob Lamp

The distinctive design of the Jacob lamp is sure to grab your eye, offering a fantastic choice for various settings. It serves as a perfect way to infuse a touch of elegance into your workspace, dining room, or any space in need of a chic accent.

Jacob Flower Vase

The distinctive design of the Jacob vase is sure to grab your eye, offering a fantastic choice for various settings. It serves as a perfect way to infuse a touch of elegance into your workspace, dining room, or any space in need of a chic accent.

Jacob Vase

The distinctive design of the Jacob vase is sure to grab your eye, offering a fantastic choice for various settings. It serves as a perfect way to infuse a touch of elegance into your workspace, dining room, or any space in need of a chic accent.

Gary Lamp

The Gary lamp showcases a distinctive and eye-catching glaze, making it an ideal decoration for a variety of environments. Perfect for enhancing your home office, kitchen, or any other area that could use a hint of sophistication.

Gary Flower Vase

The Gary vase showcases a distinctive and eye-catching glaze, making it an ideal decoration for a variety of environments. Perfect for enhancing your home office, kitchen, or any other area that could use a hint of sophistication.

Gary Vase

The Gary vase showcases a distinctive and eye-catching glaze, making it an ideal decoration for a variety of environments. Perfect for enhancing your home office, kitchen, or any other area that could use a hint of sophistication.

Scott Lamp

The Scott lamp features a unique and attention-grabbing glaze, making it a perfect addition to different settings. Great for sprucing up your workspace, dining area, or any space in need of a touch of elegance.

Scott Flower Vase

The Scott vase features a unique and attention-grabbing glaze, making it a perfect addition to different settings. Great for sprucing up your workspace, dining area, or any space in need of a touch of elegance.

Scott Vase

The Scott vase features a unique and attention-grabbing glaze, making it a perfect addition to different settings. Great for sprucing up your workspace, dining area, or any space in need of a touch of elegance.

Brandon Lamp

The Brandon lamp’s distinctive glaze is sure to catch your eye, making it an ideal choice for various settings. Perfect for adding a touch of elegance to your workspace, dining area, or any room that needs a little extra flair.

Brandon Flower Vase

The Brandon vase distinctive glaze is sure to catch your eye, making it an ideal choice for various settings. Perfect for adding a touch of elegance to your workspace, dining area, or any room that needs a little extra flair.

Brandon Vase

The Brandon vase distinctive glaze is sure to catch your eye, making it an ideal choice for various settings. Perfect for adding a touch of elegance to your workspace, dining area, or any room that needs a little extra flair.

Benjamin Lamp

The unique glaze on the Benjamin lamp will definitely grab your attention, making it a great option for different spaces. It’s just what you need to add a bit of sophistication to your office, dining room, or any area that could use a stylish touch.

Benjamin Flower Vase

The unique glaze on the Benjamin vase will definitely grab your attention, making it a great option for different spaces. It’s just what you need to add a bit of sophistication to your office, dining room, or any area that could use a stylish touch.

Benjamin Vase

The unique glaze on the Benjamin vase will definitely grab your attention, making it a great option for different spaces. It’s just what you need to add a bit of sophistication to your office, dining room, or any area that could use a stylish touch.

Raymond Lamp

The distinctive finish of the Raymond lamp is sure to catch your eye, making it an excellent choice for various settings. It’s the perfect way to bring a touch of elegance to your workspace, dining area, or any room in need of a fashionable accent.

Raymond Flower Vase

The distinctive finish of the Raymond vase is sure to catch your eye, making it an excellent choice for various settings. It’s the perfect way to bring a touch of elegance to your workspace, dining area, or any room in need of a fashionable accent.

Raymond Vase

The distinctive finish of the Raymond vase is sure to catch your eye, making it an excellent choice for various settings. It’s the perfect way to bring a touch of elegance to your workspace, dining area, or any room in need of a fashionable accent.

Jerry Lamp

The unique design of the Jerry lamp is guaranteed to capture your attention, making it a great option for different environments. It is an ideal way to add a hint of sophistication to your office, dining space, or any area that requires a stylish touch.

Jerry Flower Vase

The unique design of the Jerry vase is guaranteed to capture your attention, making it a great option for different environments. It is an ideal way to add a hint of sophistication to your office, dining space, or any area that requires a stylish touch.

Jerry Vase

The unique design of the Jerry vase is guaranteed to capture your attention, making it a great option for different environments. It is an ideal way to add a hint of sophistication to your office, dining space, or any area that requires a stylish touch.